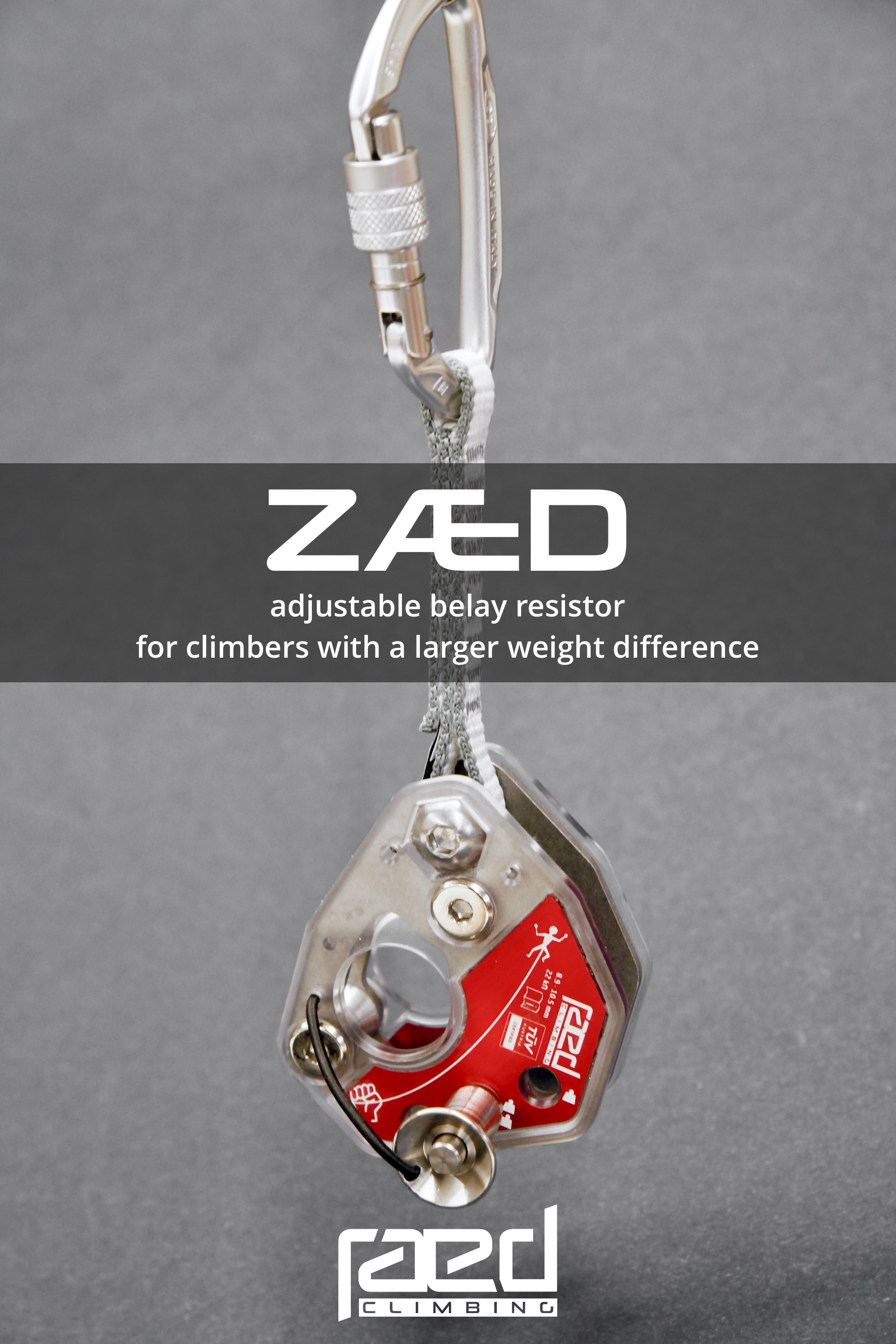

Why your slackline gear should never be made of aluminium

tl;dr: It's much safer and more environmental friendly to use slackline gear made of steel. High strength aircraft aluminium, especially in CNC-machined parts, is well known to crack under cyclic loads while steel is a lot more resistant to fatigue. Steel needs less energy during the production cycle while aluminium has a very bad environmental footprint.

There's some change happening in the slackline community, that we want to take a closer look at today: Aluminium gear for longlines and highlines. This started with slackline pulley systems and went on to weblocks and nowadays even shackles or shackle-weblock-combinations. We believe that it's worth discussing this "trend" and showing the slackline community in detail, why we believe this can be very dangerous. To understand, why we believe this, we have to explain some of the properties of aluminium and steel to compare them afterwards.

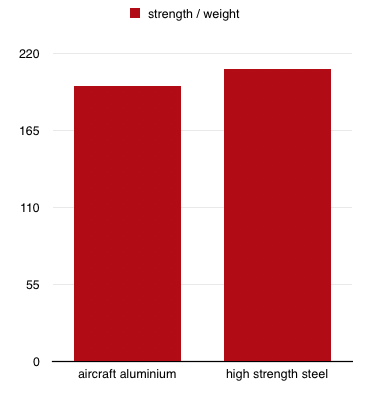

Physical properties of aluminium and steel

Aluminium is lighter than steel. That makes it a very attractive material to create sports gear because heavy things need more energy to be moved during sports. Steel's specific weight is nearly 3 times higher than the specific weight of alu. On the other hand steel is is much stronger because alu is a very soft material. That's why alu is only used in hardened alloys and why aluminium gear is usually much more bulky than steel gear. You simply need more aluminium to create very strong designs. High strength steel is an alloy of iron that drastically improves the properties compared to alu: the strongest available steel alloys are more than 3 times stronger than the strongest alu alloys, so the weight advantage of alu can be outcompeted by steel if it's used in clever engineered designs that allow a minimum use of material. This means that constructions made of high strength steel are even stronger than constructions of the same weight of aluminium.

strength/weight ratio of aluminium and steel

strength/weight ratio of aluminium and steel

Mechanical properties of aluminium and steel

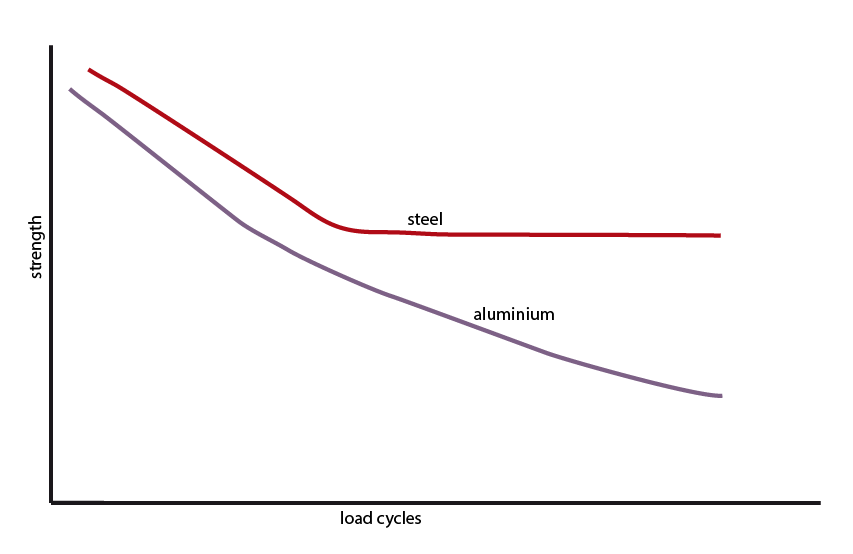

1. Fatigue resistance

Longlining and highlining become more and more to massive tricklines. Huge bounces and crazy leashfall tricks become usual nowadays. But also many leash falls from beginners on highlines are seen much more often as highlining becomes a popular sport even with festivals taking place to encourage newbies. The forces that result from all these moves on slacklines, lead to fatigue.

Fatigue can be described as weakening of a material after a certain amount of load cycles. The more load cycles some material has seen, the weaker it gets. There is an amazing difference in the fatigue resistance between aluminium and steel. While steel has a so called fatigue limit, an amount of load cycles from when it won't weaken any more, aircraft aluminium doesn't know any limit in fatigue. It weakens and weakens with growing load cycle numbers until it finally breaks. Breaking of aluminium parts that see regular cyclic load can be very well observed in other sports, cycling for example. While a broken part at a bicycle will most propably leave you with minor injuries, a broken part in a highline rig can be a very serious issue. The author himself went through 2 broken alu handlebars, one broken alu seat post and one broken alu frame during the last 15 years of cycling. So be assured: Breaking of aluminium due to high load cycles definitely IS an issue and we should take this very serious in slacklining.

S-N curve showing the fatigue limit of steel which is a huge benefit

S-N curve showing the fatigue limit of steel which is a huge benefit

"But it's aircraft aluminium, if it's good for planes, it's also good for slacklines, right?" Well, the answer is yes and no. Planes also see lots of fatigue. That's why all parts of planes that are made of aluminium and see high load cycles are inspected, maintained and changed high frequently. Some highly important parts of planes that are not allowed to break under any circumstances are not made of aluminium at all but of steel or titanium for that reason. Inspections and maintanance of airplanes contains daily, weekly, monthly and yearly visual and technical inspections as well as regular complete changeovers of critical parts. Ultrasonic and X-Ray are used to detect micro fractures in the materials. Only these very regular maintenance routines make the use of aluminium in planes possible.

But let's be honest: Who in the slackline community can do all of this for his/her slackline gear on a regular base? And there's another obvious problem: Aluminium won't "tell" you if it's going to break within the next time. It shows nearly no deformation before a complete failure. Aluminium simply cracks up in the split part of a second. Cracks in the material are invisible tu the human eye - that’s why airlines use X-Ray and Ultrasonic to find them. Steel on the other hand shows huge deformations which can be recognized as an alerting warning sign to change the gear before a complete failure.

broken bicycle parts due to micro-cracks and cyclic loading causing fatigue

broken bicycle parts due to micro-cracks and cyclic loading causing fatigue

2. Resistance after external force influences

Aluminium is a very soft material compared to steel. The typical hardness of 7075 aluminium alloys is about 110-150 HBW while the steels that are used in Raed Slacklines gear have a hardness between 340 and 530 HBW, depending on which part it is. These hardness describes how easy it is to deform the surface of your gear by the impact of a force. This force can be applied by letting your gear fall onto rock, crashing it against other gear in your gear bag, you get the picture. As aircraft aluminium is so much softer than high strength steel, it's quite easy to add deformations to aluminium slackline gear. You may most certainly know these deformations from aluminium biners from your climbing quickdraws or other aluminium parts you own. Sometimes even microscopic cracks appear in the aluminium. Invisible to the human eye but absolutely horrific for the safety of the gear. These deformations change the geometry of the gear, which will make force peaks appear in the gear structure. Such force peaks can easily lead to bigger cracks or even complete breaking of aluminium gear, especially when it's used in cyclic load conditions like it's the case in slacklines.

That's why it's important to change aluminium gear after heavy impacts like letting it fall down the crag or even just letting it fall onto hard rocks. The autor himself saw one of his climbing carabiners breaking just from falling onto rock from some (2-3) meters of height, so be assured: Aluminium being damaged or even breaking by external force impacts definitely is a serious issue too. High strength steel is less sensitive to external force influences. You can give it some really hard times, maybe the painting is scratched afterwards but it's still good to go. That's one of the biggest advantages of steel compared to aluminium.

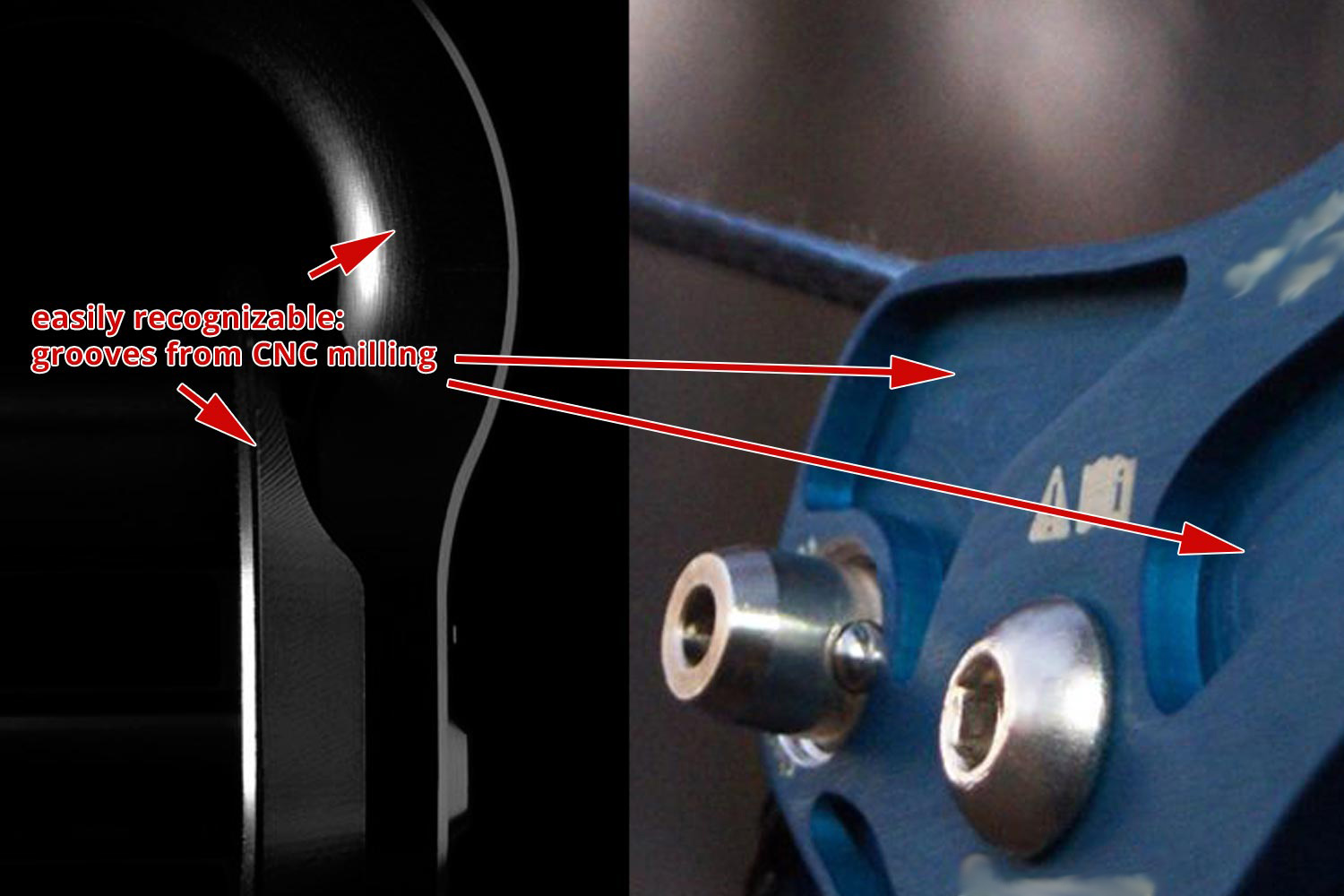

3. Predetermined breaking points created by CNC mills

CNC mills are machines that mill nearly any form you need out of a solid block of aluminium. This enables gear designers to create forms that have never been available before, like aluminium shackles or one piece aluminium weblocks. The promised advantage: By shaping the material the way you want you can create stronger and lighter gear in a very convinient way. If there only weren't the BUTs. One huge BUT is the price. CNC milling is much more expensive than any other production process available. But the price is not the most important one.

Much more important is, that CNC milled pieces are a lot weaker than forged aluminium parts. The reason: CNC mills cut the material out of the solid block in many small steps. This process leaves small but visible and palpable scratches in the surface which create exactly the same problem as the external force influences described above. Any one of these scratches is a predetermined breaking point. This is very well known from other sports like cycling. Crank arms for example have been tried to produce in CNC mills during the 1990s and 2000s. The result: lots of broken cranks (remember the picture above?), lots of injured cyclists. The reason: crank arms are bicycle parts that are (exactly like slackline gear) used under very cyclic loads. And cyclic loads + predetermined breaking points = broken gear. It's that simple.

That's why all major cycling brands changed back to forging crank arms. And every climbing carabiner out there is forged too - for very good reasons. We strongly believe that slackline gear producers should learn from the mistakes of other sports in the past. CNC milling as it is available these days is a very bad solution for creating slackline gear.

easily recognizable, even in the producers' own images: grooves from CNC milling (brand names have been erased)

easily recognizable, even in the producers' own images: grooves from CNC milling (brand names have been erased)

4. Incompatible material combinations

As mentioned above, aluminium is softer than steel. This will make it being deformed and left with damages when used together with steel gear connected directly to each other. It's the same as the marks in your climbing quickdraws after you used them in these sharp edged fixe hangers. These marks are predetermined breaking points which can lead to the same failures as the deformations made by external force influences or the scratches made by CNC mills. The result is always the same: The material is weakened in this point which can lead to complete failure after cyclic loading.

The problem: Sometimes even the producers of the gear don’t know about that problem in detail and recommend such combination in facebook groups like SlackChat. And even PRO slackliners post beautiful images of crazy highlines or bouncy tricklines with these dangerous material combinations. We really believe they don’t do this by bad intentions - the community simply doesn’t know better yet. Slacklining hasn’t gone through lots of broken gear like Mountainbiking yet. But the reason for this isn’t ultrasafe slackline gear - it’s simply there are way less slackliners than mountainbikers. So it is just a question of time when first accidents happen. We don’t want to blame anybody, neither producers nor athletes on this. We want to educate on this sensitive issue. Let’s learn from the painful mistakes of other sports before such mistakes become fatal in ours.

deformations caused by steel on aluminium use (brand names have been erased)

deformations caused by steel on aluminium use (brand names have been erased)

5. Corrosion resistance

Both, aluminium and steel can corrode. Corrosion weakens metals, so they can break under much lower loads than their expected MBS. The corrosion protection of steel parts is quite simple: They are mostly powder coated, so they can't get in touch with any corrosive substances like water or sweat anymore. Aluminium parts are usually anodized. This very thin cover of the aluminium itself prevents it from usual corrosion. The barrier oxide film that is bonded strongly to its surface can also be colored very nice. The problem: It doesn't prevent from sweat corrosion, which is quite common in sports usecases and it doesn't prevent from seawater corrosion too. Especially when used in saltwater environments, aluminium becomes a sacrifical anode when being in contact with other metal parts that are made of steel, as it's usual in any carabiner, slackline shackle, hangover and so on. They all contain steel parts too, which will make the aluminium corrode in very short time periods.

In addition to this, aircraft aluminium is even less resistant to corrosion than weaker aluminium alloys (3). It's true that steel isn't completely resistant to seawater environments too but there is one huge difference: The time it takes to weaken steel parts is much longer. So we have to face it: Another big downside for aluminium gear here.

Corrosion on an anodized aluminium handlebar caused by human sweat

Corrosion on an anodized aluminium handlebar caused by human sweat

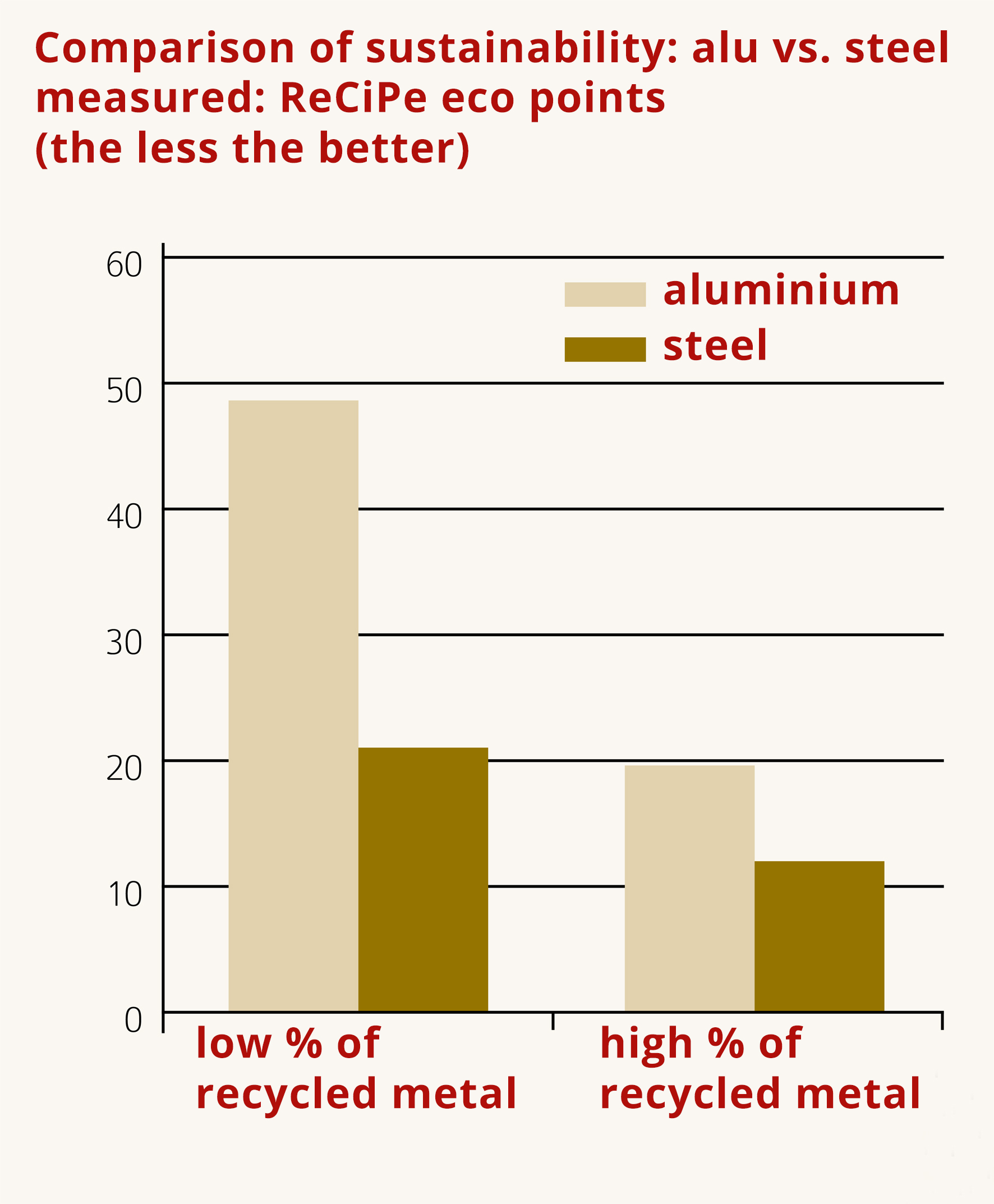

Environmental Aspects

Steel is mostly called the "envirionmental friendly metal" while aluminium is a real bad boy when it comes to the environmental footprint of the production. But how bad is it in numbers? The city of Oss in the Netherlands wanted to know exactly and started some research on this topic. They found that in all life cycle scenarios, one that contained large portions of recycled metal and one that contained low amounts recycled material, steel was the clear winner regarding environmental friendlyness. Aluminium collected about twice the ecopoints (the lower the better) in each scenario (4). The study was done in comparison to usual steel. Raed Slacklines uses high strength steel that is about 4 times stronger than usual steel. That's why we need even less steel for our constructions what makes raed slacklines gear even more environmental friendly.

And there are even more, very concerning facts about aluminium: the biggest Aluminium sources are in areas where tropical forest and agricultural areas exist. These areas are completely destroyed to source aluminium and they will never return (5). The production aof aluminium produces 44% more CO2 than steel (2). And to win aluminium from the ground the companies have to waste huge countrysites that are poisoned with red mud after the process (1). In this areas no farming is possible anymore for many decades.

Ecopoints of aluminium and steel - the lower the better

Ecopoints of aluminium and steel - the lower the better

wasted, red mud poisoned land after winning aluminium

wasted, red mud poisoned land after winning aluminium

Cost

Steel parts are mostly constructed from steel plates that are laser cut or water cut. This production process is widely spread, uses very little material and is very cost effective. CNC milled aluminium parts have to be milled out of a solid block of aluminium which makes the most of this aluminium become milling garbage. This garbage needs to be melted again to become reusable which uses very high amounts of energy and - you guess it - is not environmental friendly at all. That's why CNC milled aluminium parts are much more expensive than steel constructions.

Conclusion

In this short note we tried to collect the most important facts about the properties of aluminium, which in our opinion make this material improper compared to steel when it comes to the use in slackline gear. We know there are lots of more resources about this topic like the many articles in "bergundsteigen" and other alpine club publications that point in a very similar direction. Aluminium is a great choice for climbing gear, which doesn't see any cyclic loads at all. The loads of slacklining make it a very complex issue, especially when external force impacts have been applied before. This becomes a more serious issue since even longlines and highlines become huge tricklines. We strongly believe, that manufacturers of slackline gear should find gear solutions, that don't put slackliners into possibly harmful situations. That's why we at raed slacklines will continue to produce all load bearing parts of our slackline gear of high strength steel. We believe, this is a much safer and more environmental friendly way of slacklining. And we would like to encourage all slackline gear producers out there to do the same. Slacklining is a very safe sport and we all care about our environment - let's keep it that way. Keep the balance! :)

Sources

(1): https://en.wikipedia.org/wiki/Aluminium#Natural_occurrence

(2): https://www.tatasteeleurope.com/static_files/Downloads/Automotive/Case%20Studies/Tata%20Steel%20AM%20-%20Sustainable%20Steel%20for%20Cars%20-%20Case%20study%20DE.pdf

(3): http://www.totalmateria.com/Article14.htm

(4): https://www.pressebox.de/pressemitteilung/institut-feuerverzinken-gmbh/Nachhaltiger-als-Aluminium-Feuerverzinkter-Stahl-und-Aluminium-im-Vergleich/boxid/725038

(5): https://www.umweltbundesamt.de/sites/default/files/medien/378/dokumente/umsoress_fallstudie_bauxit_guinea_finale_version.pdf

DEU

DEU

Validate your login

Sign In

Create New Account