Efficiency comparison test of slackline pulley systems for longlines

Anytime when you want to walk across a slackline, you have to tension it first. The only eception from this is a rodeo line - which is completely untensioned and therefore much harder to learn and control because it moves completely free under the feet of the slackliner.

Tensioning a slackline can be an easy task for very short lines - and it can need quite the effort for longer lines. If you don't tension your longline enough, you might end up standing on the ground in the middle of the line, without being able to cross it completely (sending it).

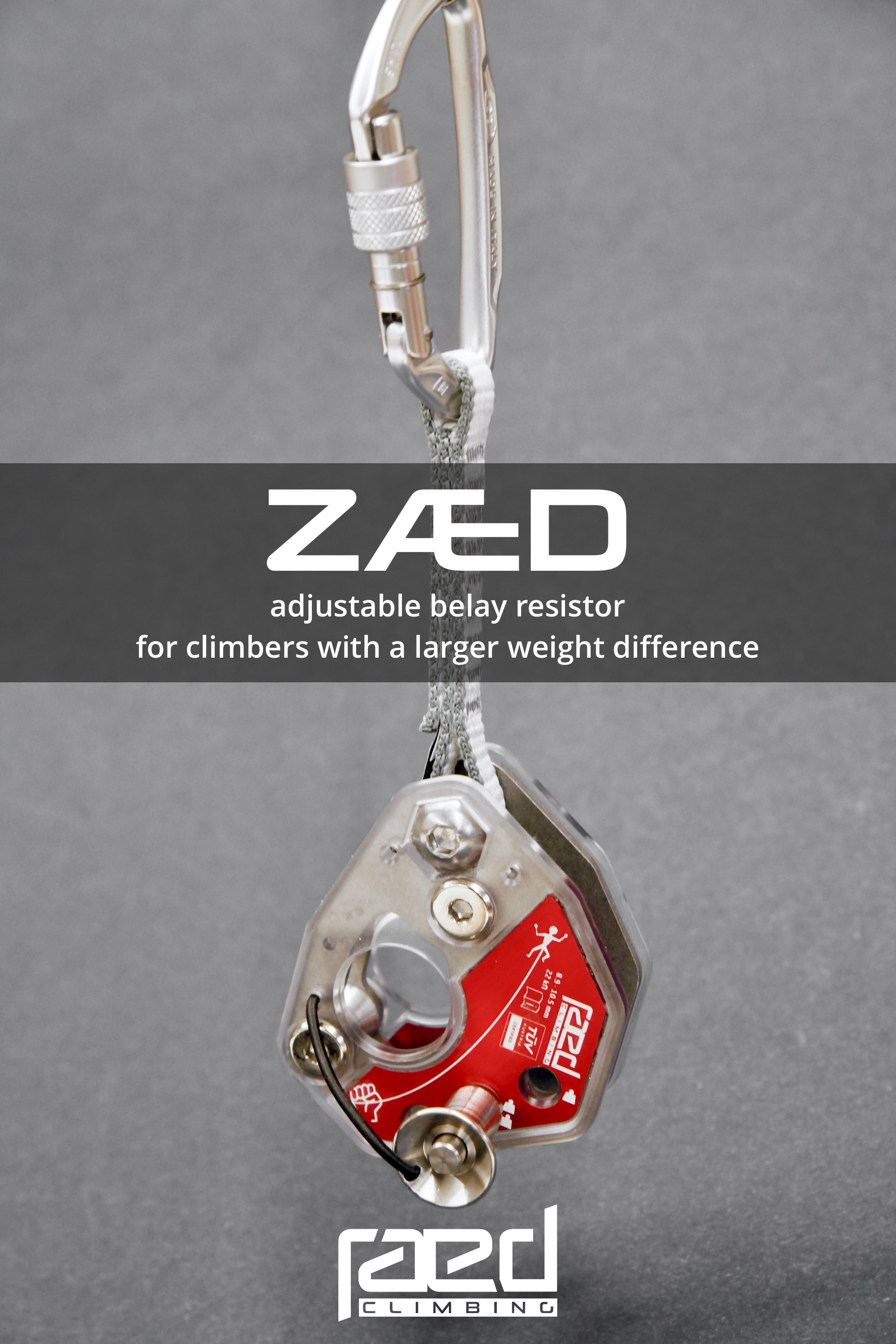

The most efficient slackline pulley system in the world.

We are very bold in our advertising. From the beginning we proudly claimed to have engineered the most efficient slackline-pulleysystem out there. As you can see, Martha is able to tension her high tension Nylon Longline one handed with the PRO Pulley system.

While classic 5:1 slackline pulleysystems achieve an average efficiency of about 50%-65% (A.Schulz et al., 2013, https://vimeo.com/74945094), our goal was set a lot higher: We wanted a 9:1 pulley system, so it contains more ball bearings, that might create more (!) friction, but we wanted it to be much more efficient at the same time - in other words: we wanted double the bearings but less friction in total. So we had to absolutely minimize the friction. This is where the engineering process started and - long story short - we found a way to achieve this.

Last month one of our potential customers sent us the question, how efficient it really is and how it compares to the competitors in the market. So we used the first sunny days of spring to head out to the park and measure some values to start the calculations on the efficiency of our PRO pulleysystem.

We measured the force that is needed to pull the rope out of the pulley system to tension a longline to a certain load in the line. Then we put these values into a ratio, comparing it to the theoretical mechanical advantage that would be achieved without any friction in the system. The ratio of the real value to the theoretical value is called the "efficiency" of the whole pulley system.

In addition to the averaged values of the 2013 OID study from Alexander Schulz, we also added the measured values from Samuel Volery et al., who published values about the efficiency of his Hangover Pulley System in 2017 (https://www.youtube.com/watch?v=rEdHMDOHbOw), to compare them with the field. As the HPS produces quite different values with different webbings, we calculated the average value of all the measured 9:1 values to compare them with the averaged values of the rope pulley systems.

As expected, the numbers show that the HPS is the least efficient way to tension long slacklines compared to efficient rope pulley systms. It takes you nearly 50% more power to tension with a HPS compared to the raed PRO pulley system.

DEU

DEU

Validate your login

Sign In

Create New Account